Skift sprog :

Quickly assembled cable guidance with sensors in storage and retrieval units from ATZ and Raiser

The ready-to-install "Storage Bee" for high-bay warehouses relies on trough-free energy chains.

In material handling for small and medium-sized companies, everything has to go exactly right: For each order, there must be a smooth transition between individual process steps without downtime or maintenance. With the Storage Bee, material handling specialists ATZ and Raiser Engineering have created a storage and retrieval unit for this target group. Energy and data is guided by the simply assembled autoglide 5 energy chain, which enables predictive maintenance and prevents unplanned downtimes thanks to i.Sense sensor technology.

Products used

autoglide 5

i.Sense sensor technology

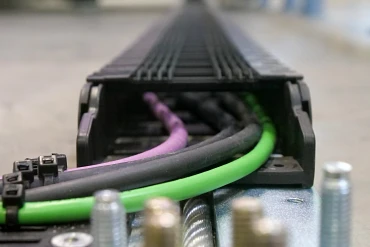

The autoglide 5 rests on a steel cable that ensures safe movement.

The power supply and all other media can be guided via the energy chain.

Vertical movement is also possible with igus components.