Skift sprog :

Modstandsdygtig over for snavs, støv og spåner: produkter til træbearbejdningsindustrien

Find nemt produktløsninger i henhold til anvendelsestype

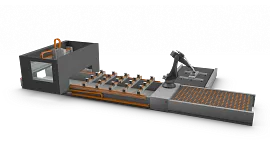

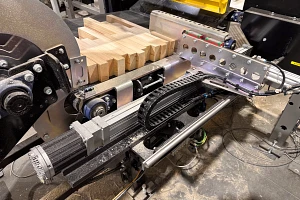

Motion Plastics til bevægelige applikationer hjælper med at reducere logistik-, installations- og gennemløbstider. I træbearbejdningsmaskiner og CNC-bearbejdningscentre sikrer vores energiforsyningssystemer en kontrolleret bevægelse af kabler og hydrauliske og pneumatiske slanger, selv under ugunstige forhold med støv og spåner. Vores lineære føringer og glidelejer og kuglelejer kræver heller ingen ekstern smøring eller vedligeholdelse. Det gør dem ideelle til træbearbejdningsindustrien, da spåner, støv og snavs ikke kan sætte sig fast på lejepunkterne takket være tør drift.

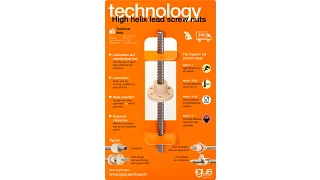

dryspin® prøve på spindelteknologi

► Til formatjusteringer og positioneringsopgaver

► Fri for smøring og vedligeholdelse

► Højere effektivitet

► Længere levetid på grund af asymmetri

► Medieresistent

► Støjsvag, vibrationsfri drift på grund af gevindgeometri

► Forudsigelig levetid online

Succeshistorier

Måske er du også interesseret i

Genbrug gjort nemt

Energiforsyningssystemer, uanset producent, eller anden industriel plast: chainge-platformen gør den cirkulære økonomi nem.

Vi kommer til dig

Se al motion plastics bekvemt i dine lokaler, enten som en præsentation på kontoret eller i en showtruck udenfor. Alt er muligt.

Rådgivning

Jeg vil med glæde besvare deres spørgsmål personligt.

Levering og vejledning

Personlig betjening:

Mandag til fredag fra 7:00 til 20:00.

Lørdag fra 8:00 til 12:00.

Online:

24h