Skift sprog :

Passager landgangsbroer

Uden den ville det være meget mindre behageligt at flyve: Passagerbroen (også kendt som landgangsbroen eller passagerbroen) gør det muligt at gå ombord på fly på en beskyttet måde i tusindvis af lufthavne verden over. I flyvningens barndom var det endnu nemmere at komme om bord. De små propeldrevne fly havde små indbyggede trin, som blot kunne sænkes. Selv i dag bruger mindre fly generelt indbyggede trapper, da hældningen i passagerbroen ellers ville være for stejl.

Hvordan ville det se ud uden passagerbroen? Moderne trafikfly har boardinghøjder på op til 4 meter over jorden. På gigantiske jetfly som Airbus A380 skal passagererne endda gå om bord på to niveauer. Det ville kræve meget høje trapper. Og børnefamilier, ældre og svagelige passagerer ville have meget sværere ved at komme om bord på flyet. For slet ikke at tale om beskyttelse mod vind og vejr.

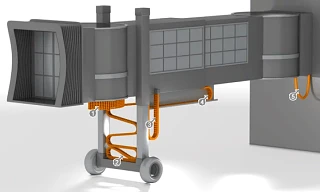

Princippet for passagerbroen er enkelt: Som regel er en del af systemet fast forankret til lufthavnsbygningen. En anden del er fleksibelt monteret, så den kan lægge til ved forskellige flytyper. For eksempel skal der kompenseres for forskelle i højden på flydøren samt forskellige flylængder og -bredder. Til dette formål består en gangbro normalt af flere rør, der kan teleskoperes ind og ud, og en eller flere løfteenheder. Denne teleskopiske landgangsbro er den mest fleksible variant af passagerlandgangsbroen. Mindre fleksible designs er ofte kun egnede til bestemte flytyper, hvilket begrænser lufthavnsoperatørernes fleksibilitet.

Passagerbroen flyttes ved hjælp af elektriske motorer. Disse kræver strøm- og datakabler til kontrolsystemet. De enkelte elementers bevægelser er ikke særlig hurtige. Alligevel skal kablerne beskyttes mod skader. Da de normalt er placeret uden for gangbroen, skal de også kunne modstå vind og vejr.

Fordele ved igus® produkter i passagerbroer

Da flyenes tomgangstider bliver stadig kortere, og passagerbroerne skal fungere pålideligt, skal den mekaniske bevægelse køre problemfrit. Hvis en passagerbro går i stå, kan det betyde et øjeblikkeligt økonomisk tab for lufthavnsoperatøren, flyselskabet og også for passagererne, som gerne vil flyve komfortabelt, sikkert og til tiden.

Den høje pålidelighed af igus® produkter taler for deres brug i passagerbroen. Kablernes bevægelser i gangbroen kan styres sikkert med vores e-kædesystemer. Slagene er for det meste vandrette bevægelser i teleskoptunnellerne og lodrette bevægelser i løfteenhederne. E-kæden® har en lang levetid, så man kan forvente en lang levetid. De kan installeres på en pladsbesparende måde, så ingen kabler hænger ned, og det visuelle udseende ikke forringes. Al nødvendig energi kan tilføres med e-kæden®, f.eks. strøm- og styrekabler, hydraulik, pneumatik osv.

1 e-kædesystemer med roterende bevægelse som en omvendtbøjningsradius løsning 2 e-kædesystemer med løftebevægelse -

installationstype " zig-zag "

3 Løftebevægelse e-kædesystemer

- installationstype "ophængt " 4 E-kædesystemer til vandret bevægelse - installationstype

type uunderstøttet eller glidende 5 Kabelbeskyttelse i flere akser e-kædesystemer styrer og beskytter i bevægelige applikationer, tredimensionelt

e-kædesystemerne reducerer de nødvendige kabellængder med mere end 50 % (med medium indføring) og forhindrer eksterne mekaniske belastninger på kablet, som f.eks. ukontrolleret vuggen, svingning, fastklemning osv. De lave vedligeholdelseskrav reducerer nedetiden. E-kædesystemerne fungerer ideelt sammen med igus® chainflex® kabel. Ligesom e-chain® kan de modstå varme, sol, regn og sne.

Produkter til brug i passagerbroer

Energikæde

Vellykket i brug

Rådgivning

Jeg vil med glæde besvare deres spørgsmål personligt.

Levering og vejledning

Personlig betjening:

Mandag til fredag fra 7:00 til 20:00.

Lørdag fra 8:00 til 12:00.

Online:

24h