Skift sprog :

Plastkuglelejer: Smøring og vedligeholdelsesfri

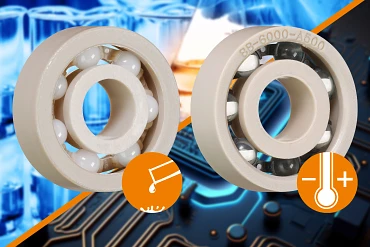

Kuglelejer erstatter glidefriktion med rullefriktion, hvilket muliggør rotationsbevægelse med minimal modstand. Som regel skal de smøres for at fungere korrekt. xiros plastkuglelejer kræver ingen yderligere smøring, er korrosionsfri og fungerer ekstremt støjsvagt. Dette gør dem til et omkostningseffektivt alternativ til deres metalpendanter. Komponenterne, der består af en tribopolymerblanding, er lette, kemikaliebestandige og kan fås i ikke-magnetisk udførelse. Dette sikrer sikker anvendelse inden for medicin, emballage, fødevarer og drevteknik samt mange andre brancher.

Vores xiros kuglelejer består af en blanding af basisplast, faste smøremidler, fibre og filamenter. De anvendte kugler er normalt lavet af rustfrit stål, glas eller plast. Disse er monteret i en bur, der kan være lavet af vores egne xirodur-materialer, PA, PP eller PEEK.

Fordelene i kort oversigt

Hvor kan jeg købe kuglelejer?

Radiale sporkuglelejer, tryklejer, flangekuglelejer, kuglelejer med pilleblok, kugletransportenheder, transportruller, svingringkuglelejer og andre typer i forskellige størrelser kan findes i vores online shop. Takket være det brede udvalg af materialer er vores løsninger designet til en lang række brancher og kan også implementeres i din specifikke applikation.

Kuglelejer efter mål

Det kan og behøver ikke altid være en katalogvare. Derfor tilbyder vi dig muligheden for at bestille en specialfremstillet del, der afviger fra DIN-standarden, til din specifikke anvendelse. Fra idé til løsning: Uendelige muligheder takket være vores polymerkuglelejer. Vi rådgiver dig gerne.

Materialer og stoffer

Vores materialer er velegnede til en lang række anvendelsesområder og er kendetegnet ved en lang række fordele: Fra omkostningseffektive allround-materialer og varmespecialister til kemikaliebestandige materialer. Få mere at vide om de anvendte kuglematerialer.

Nye produkter

Vi arbejder løbende på at videreudvikle eksisterende og nye produkter for at forbedre teknologien i din applikation og reducere omkostningerne. Hvert forår og efterår lancerer vi spændende polymerkuglelejeprodukter på messer. Hold dig altid opdateret her.

Hvor bruges kuglelejer? Og hvilke typer findes der?

Det er umuligt at forestille sig maskinteknik uden kuglelejer. Der findes forskellige designs, hvor komponenternes dimensioner og tekniske sammensætning afhænger af specifikationerne for den industrielle anvendelse. De mest almindeligt anvendte typer er vist nedenfor.

Radialt kugleleje i henhold til DIN 625:

Denne type kugleleje absorberer radiale kræfter og anvendes overalt, hvor komponenter roterer. I bilindustrien findes radiale rillelejer f.eks. i chassiset, hvor kuglelejerne anvendes til at afstive og føre akslerne. Der opstår altid en radial kraft, når akslen udfører en roterende bevægelse.

Vinkelkontaktkugleleje i henhold til DIN 628:

Dette leje er konstrueret til at absorbere både radiale og aksiale kræfter i én retning. Vinkelkontaktkuglelejer muliggør højere hastigheder og reducerer friktionen for en lang række belastninger. Vinkelkontaktkuglelejer anvendes i cykelindustrien, bilindustrien eller f.eks. i spindler på værktøjsmaskiner.

Selvjusterende kugleleje i henhold til DIN 630:

Denne type kuglelejer anvendes generelt i applikationer med lange aksler. Dette skyldes monteringsproblemer forårsaget af huller i huset. Den aksiale kraft spiller en rolle i selvjusterende lejer. Denne skal holdes lav, da rillerne i den ydre ring har begrænsede kontaktflader til rullende elementer. Den anvendes i almindelig maskinteknik.

Aksialt leje i henhold til DIN 711:

Også kaldet et aksialt dybsporet kugleleje, er denne type designet til at understøtte aksiale belastninger. De fås i en enkelt- eller dobbeltradet udførelse og anvendes allerede i talrige applikationer inden for medicinsk teknologi eller emballageindustrien.

Her kan du se, hvor vores polymerkuglelejer anvendes med succes i industrien.

Tekniske oplysninger om kuglelejer

I dette afsnit besvarer vi nogle generelle spørgsmål om kuglelejer og vores polymerkuglelejer. Blandt andet kan du læse om følgende emner:

- Hvordan er konstruktionen?

- Hvornår skal jeg skifte kugleleje?

- Oplysninger og testrapporter fra testlaboratoriet

- Hvordan monterer jeg kuglelejer?

- Hvidbog til download

Rådgivning

Jeg vil med glæde besvare deres spørgsmål personligt.

Levering og vejledning

Personlig betjening:

Mandag til fredag fra 7:00 til 20:00.

Lørdag fra 8:00 til 12:00.

Online:

24h