Skift sprog :

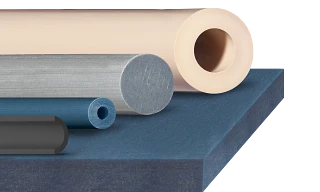

Stangmateriale i plast

Over 40 materialer til din anvendelse

Alt stangmateriale er fremstillet af vores gennemprøvede iglidur-materialer, som er specielt udviklet til bevægelige applikationer. Vores materialer er selvsmørende og kendetegnet ved en meget lav friktionskoefficient og fremragende slidstyrke. Hvert materiales specifikationer gør det til en specialist inden for et bestemt anvendelsesområde. Derfor findes der iglidur-materialer og stænger, der passer til næsten alle anvendelser, også dem, der involverer høje temperaturer og havvand, fra fødevaresektoren til bilindustrien.

Vi producerer vores stænger i overensstemmelse med

DIN EN 15860. Denne forskrift definerer kravene og testmetoderne for væsentlige egenskaber (f.eks. tykkelse, bredde og længde af plader, rundjernsdiameter og -længde, tilladte nedbøjninger af stangmaterialet) for stangmateriale fremstillet af termoplastiske polymerer til bearbejdning.

Vores sortiment af stangmateriale

Brochurer & prøveæske

Prøveæske til stangmateriale

Bestil vores gratis prøvekasse og få information om et bredt udvalg af materialer.

Brochure om stangmateriale

I brochuren om stangmateriale kan du få mere at vide om anvendelsen af iglidur stangmateriale samt oplysninger om specifikationer og forarbejdning.

CNC-designguide

Denne designguide giver dig de vigtigste principper for at designe drejede og bearbejdede dele, der er så omkostningseffektive og fremstillet så økonomisk som muligt.

Hvorfor bruge stænger lavet af iglidur?

iglidur plaststænger giver mulighed for omkostningseffektiv produktion af komponenter til bevægelige applikationer og er ideelle til fremstilling af prototyper samt små og mellemstore serier. Plader, pladestrimler, plader, runde og hule stænger fremstillet af en række forskellige højtydende iglidur-polymerer er tilgængelige fra lager. Hvert materiales specifikationer gør det til en specialist inden for et bestemt anvendelsesområde. Derfor kan du finde iglidur-stænger, der passer til næsten alle anvendelser, også dem, der involverer høje temperaturer og havvand, fra fødevaresektoren til bilindustrien. Alle iglidur-materialer er specielt udviklet til dynamiske anvendelser og har lave friktions- og slidkoefficienter.

Nye produkter på stanglager 2025

Vores mål er altid at tilbyde vores kunder den mest økonomiske løsning og at muliggøre tekniske fremskridt. Oplev vores innovationer inden for stangmateriale.

Online beregning af levetid

Vil du vide, hvor længe din komponent holder i den pågældende anvendelse?

Brug levetidsberegningen fra vores CNC-service. Simuler, hvordan valget af forskellige materialer påvirker levetiden for din komponent.

Vores tribotape-foring

Monteringsvenlig beskyttelse til alle overflader

iglidur tribotapes er tribologisk optimerede foringer og kan bruges i en lang række anvendelser. Som alle iglidur-produkter er foringerne også fremstillet af vores gennemprøvede iglidur-materialer. De kan vise deres styrke overalt, hvor der kræves lave friktionskoefficienter og høj slidstyrke. iglidur tribotape kan nemt skæres til og monteres med den valgfrie selvklæbende bagside.

iglidur liner tribotape A160

- FDA-kompatibel

- Lave friktionskoefficienter

- Slidstærk

- Let at skære til

iglidur liner tribotape V400

- Ekstremt slidstærk

- Meget modstandsdygtig over for medier

- Tåler op til +200°C på lang sigt

- Let at skære til

iglidur liner tribotape B160

- Lave friktionskoefficienter

- Slidbestandig

- Let at skære til

iglidur liner tribotape W160

- Lave friktionskoefficienter

- Let at skære til

Gratis prøve på tribotape

Bestil vores gratis tribotape-prøvekort nu, og få oplysninger om specifikationerne for vores forskellige linere.

Over 250.000 kunder verden over stoler på iglidur-materialer

AGCO | B. Braun Melsungen | Crankbrothers | FAUN Viatech | Hillrom | Kohler | KRONES | Lemken | Multipond | Nowy Styl | Sensata | TecnoSun Solar | Thaler | V-Zug | WSS Wilh. Schlechtendahl & Söhne | Zunhammer | og mange flere

Vores testlaboratorium

Vores materialer testes for friktion og slid i vores 3.800 m² store interne igus-testlaboratorium. Der udføres over 15.000 tests hvert år. Det giver os mulighed for løbende at generere data om vores produkters holdbarhed, som vi simulerer i din applikation.

Rådgivning

Jeg vil med glæde besvare deres spørgsmål personligt.

Levering og vejledning

Personlig betjening:

Mandag til fredag fra 7:00 til 20:00.

Lørdag fra 8:00 til 12:00.

Online:

24h