Skift sprog :

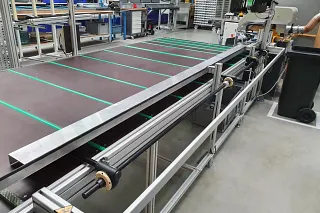

Udvidelse af delvist automatiserede maskiner med modulære gearkasser

- Hvad der var brug for: Udvidelse af en halvautomatisk savemaskine

- Krav: holdbar, lav friktion, robust

- Materiale: drygear® Apiro® gearkasse, drygear® snekkegearkasse, dryve motorstyringsenhed

- Branche: Maskinteknik

- Succes for kunden: Planlægbare og effektive produktionsprocesser, aflastning af medarbejdere

Rådgivning

Jeg vil med glæde besvare deres spørgsmål personligt.

Levering og vejledning

Personlig betjening:

Mandag til fredag fra 7:00 til 20:00.

Lørdag fra 8:00 til 12:00.

Online:

24h